Description

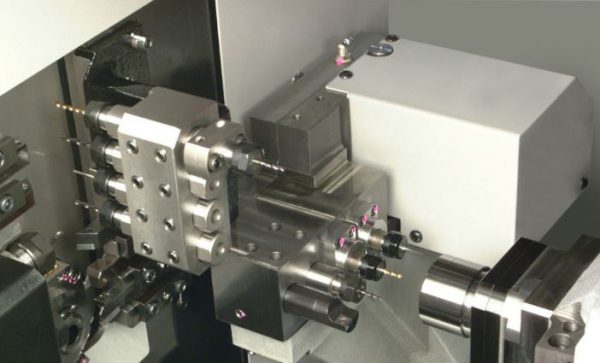

Simultaneous Machining, 21 Tool, 5-Axis Swiss Turn

The B0 family of Tsugami CNC Automatic lathes are designed to provide exactly the capability and capacity you need at an affordable price. Each incremental model adds features to the core B0 CNC lathe, representing years of Tsugami testing and research.

The B0125-III is a 12 mm, 5-axis convertible Swiss turn that adds an independent back tool post to the B0 configuration and introduces two rotary tool positions on the back tool post (optional). These improvements enable front and back spindle simultaneous machining, a proven method for reducing cycle time.

Economically priced like other B0 CNC lathes, the B0125-III includes many high end features such as Tsugami’s gang type tool post, rigid cast iron frame and 12,000 rpm main and sub spindle speed. This Swiss CNC automatic lathe offers a total of 21 tool positions: 9 OD tool positions and 12 fixed tool positions (optional 2 rotary positions for rear) for flexible 5-axis machining.

The Tsugami B0125-III is CONVERTIBLE and may be run as a traditional sliding headstock Swiss Style Lathe using the guide bushing or run without the guide bushing with the addition of an optional chucker kit. When run as a chucker, the turning center can use drawn bar stock instead of centerless ground stock, dramatically reducing remnant size and increasing shop flexibilit

| Maximum Bar Stock | 12 mm |

| # Axes | 5 |

| Sliding Headstock / Guide Bushing | YES |

| CONVERTIBLE: Run w/o Guide Bushing (chucker) | YES |

| Max Headstock Stroke w/ Guide Bushing Max Headstock Stroke w/o Guide Bushing |

210 mm 45 mm |

| # Tool Positions |

21 Max |

| # Live Tool Positions |

4 Max |

| Control | FANUC 0i-TF |

| Main Spindle Speed | 12,000 rpm |

| Sub Spindle Speed | 12,000 rpm |

| Live Tool Speed | 8,000 rpm |

| Main Spindle Motor | 1.5/2.2kW |

| Weight | 2,000 kg |

| Footprint: W x D x H | 1,665 mm × 1,135 mm × 1,700 mm |

- Enhanced 5-axis Swiss Style

- Lathe – at minimal investment cost

- Increased Back Spindle Capability – Spindle plus 8 fixed and rotary tools for simultaneous machining

- 21 Total Tool Positions – 9 OD and 4 fixed front, 8 fixed rear or 6 fixed and 2 rotary (option)

- Back Milling Operations – off-center drilling/tapping and end milling may be performed simultaneously with main spindle (option)

- 210 mm Stroke, 45 mm when used in chucker mode

- Rapid Traverse Rate of 32 m/min– Shortens idle and cycle times

- Enriched NC Functions Standard – tool nose radius compensation, chamfering and corner rounding and cutoff detection, plus many more…

- Fanuc 0i-TF CNC Control

Reviews

There are no reviews yet.